Top Lift Companies in London: Offering High Quality Installations and Maintenance

Top Lift Companies in London: Offering High Quality Installations and Maintenance

Blog Article

Looking Into the Globe of Elevators: Common Issues Encountered by Different Lift Devices

As we browse through the upright transport systems of modern-day structures, elevators attract attention as an indispensable part of our every day lives. Nonetheless, behind their seamless procedure lies a globe of elaborate mechanisms that can occasionally come across challenges. From hydraulic lifts to traction systems and machine-room-less layouts, each lift type features its set of typical issues. Comprehending these challenges is essential for making certain the smooth performance of these important systems. Allow's explore the intricacies that underlie the procedure of elevators and the prospective concerns that can emerge, clarifying the detailed web of lift mechanisms.

Hydraulic Lifts

Hydraulic lifts, often preferred for low-rise buildings, use fluid stress to regulate the activity of the lift vehicle (lift repair companies). This device involves a hydraulic pump pushing oil into a cylinder, triggering the lift to relocate the wanted direction. While hydraulic elevators are understood for their smooth and silent procedure, they do come with their own collection of usual concerns

One prevalent trouble with hydraulic lifts is oil leak. Furthermore, issues with the control system, such as malfunctioning valves or a malfunctioning pump, can cause disruptions in the lift's motion.

Routine maintenance and prompt repair work are vital to guarantee the smooth functioning of hydraulic lifts. By resolving these typical issues proactively, structure proprietors can reduce downtime and ensure the safety and security and effectiveness of their vertical transport system.

Traction Elevators

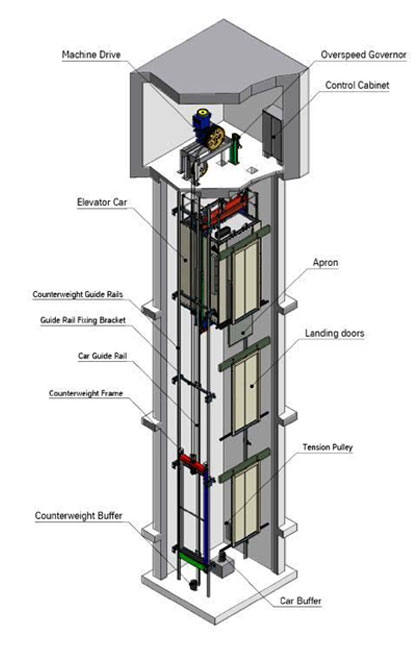

When considering upright transportation systems in structures, one more common kind apart from hydraulic elevators is the grip elevator. Traction lifts operate making use of a system of ropes and counterweights that move the lift cars and truck by gripping onto the hoist ropes. This device permits smoother and much faster vertical transport compared to hydraulic systems.

Among the common concerns encountered by grip elevators is rope wear. The consistent movement of the ropes within the traction system can bring about damage gradually, potentially creating the elevator to breakdown or become hazardous for usage. Regular assessments and maintenance of the ropes are necessary to make certain the elevator's correct performance and security.

An additional issue that traction lifts might come across is related to the control system. Issues with the control system can lead to problems such as irregular movement, delays in feedback times, or perhaps total closures. Normal testing and maintenance of the control system are critical to avoid such problems and make sure the lift's reliability.

Machine-Room-Less (MRL) Elevators

One of the key parts of MRL elevators is the portable gearless traction equipment that is set up within the hoistway. This maker successfully drives the lift vehicle without the need for cumbersome equipment located in standard traction lifts. Furthermore, MRL lifts commonly make use of a counterweight system to stabilize the automobile, more improving their power efficiency.

In spite of their benefits, MRL elevators may deal with obstacles related to repair and maintenance as a result wikipedia reference of the restricted area for tools installation. Ease of access for servicing parts within the shaft can be limited, calling for specialized training for specialists. Appropriate upkeep routines and normal evaluations are important to make certain the ongoing smooth procedure of MRL lifts.

Overloading and Weight Limit Issues

Overloading and weight limit concerns are essential problems in lift operations. Elevator manufacturers layout raises with certain weight capacities to ensure guest safety and security and devices longevity.

When lifts are overwhelmed, it puts excessive strain on the electric motor, cable televisions, and other parts, possibly causing malfunctions or break downs. Safety and security systems such as sensors and overload sensing units are in place to stop elevators from relocating if they identify excess weight. In addition, surpassing weight internet limits can cause increased power intake and deterioration on the lift system.

To reduce straining problems, constructing managers must prominently present weight restrictions in elevators and enlighten occupants on the relevance of adhering to these limitations - lift repair companies. Normal maintenance checks by certified specialists can additionally help make sure that elevators are operating within risk-free weight criteria. By attending to overloading and weight restriction concerns proactively, building owners can improve lift safety and efficiency

Electric System Failures

Exceeding weight restrictions in elevators can not only cause mechanical concerns but likewise possibly add to electric system failures within the lift facilities. Electric system failings are an important problem in elevator operation, as they can cause unforeseen closures, breakdowns, or also safety and security hazards. One common electrical problem is the overheating of elements as a result of excessive current flow triggered by overwhelming the elevator beyond its capability. This can result in harm to the control, motor, or electrical wiring systems, leading to expensive repair services and downtime.

Regular upkeep and inspections are critical to determine and resolve potential electric issues without delay, guaranteeing the secure and efficient operation of lift systems. By sticking to weight limitations and performing regular electrical system checks, structure owners can minimize the risk of electrical failures in lifts.

Conclusion

Hydraulic lifts, typically favored for low-rise structures, utilize fluid stress to regulate the motion of the lift automobile.When considering upright transport systems in buildings, an additional typical kind aside from hydraulic lifts is the grip elevator. Grip lifts operate making use of a system of ropes and counterweights that relocate the elevator cars and truck by gripping onto the hoist ropes. Unlike standard lifts that need a separate maker area to house the equipment, MRL elevators incorporate most of the elements within the shaft, getting rid of the demand for a devoted maker area.In conclusion, elevators deal with common concerns such as hydraulic breakdowns, traction system failures, and electrical system problems.

Report this page